SHINKO ELECTRIC INDUSTRIES CO., LTD.

SHINKO ELECTRIC INDUSTRIES CO., LTD.

The Shinko Group upholds "Responsibility to Individual" in its Corporate Vision of the Shinko Way, and its Corporate Values are committed to ensuring the safety of its employees by providing a safe and comfortable working environment. Shinko has put in place a company-wide safety and health plus fire and disaster prevention promotion system. We have adopted a management system approach to pursue continual improvements in the level of health, safety, and disaster prevention. As part of this, all employees participate actively in health, safety, and disaster prevention initiatives.

Shinko has established the Company-wide Basic Policy on Safety and Health Plus Fire and Disaster Prevention to promote these activities.

Shinko Electric Industries Co., Ltd. Company-wide Basic Policy on Safety and Health Plus Fire and Disaster Prevention

Ensuring employee safety and health is a top-priority issue for us, and we put the protection of safety as well as mental and physical health first in all our business operations. And based on the following policies, we will actively and continuously promote health and safety and fire prevention activities with the participation of all employees, aiming to realize a safe and comfortable work environment free from disasters.

- Compliance

Comply with all laws and regulations related to occupational health and safety, fire prevention, and disaster prevention, as well as internal regulations, standards, rules, and requirements.- Risk reduction activities

Identify, analyze, and evaluate hazardous and harmful factors in the workplace for essential safety, and promote continuous risk reduction activities in order to prevent occupational accidents and incidents from occurring and recurring.- Elimination of carelessness and unsafe behavior

Do not engage in carelessness or unsafe behavior (walking while distracted, not wearing protective equipment, deviating from rules, etc.) that could lead to the occurrence of occupational accidents.- Education and training

With the aim of eliminating accidents and disasters, continuously provide employees with necessary and sufficient education and training to improve their safety awareness and management standards.- Health management

Improve employees' health management awareness and create workplace environments where employees can work energetically in good physical and mental health.- Establishment of a fire and disaster prevention management system

Establish a fire and disaster prevention system based on "Company-wide Disaster Prevention Guidelines" and conduct ongoing reviews and trainings for disaster preparedness and measures to save lives, prevent the spread of damage, and restore operations in the event of a disaster, in order to minimize damage and strengthen response capabilities.- Allocation of management resources

In implementing the above, appropriate management resources will be allocated to implement effective improvements.Representative Director of Board, President

SHINKO ELECTRIC INDUSTRIES CO., LTD.

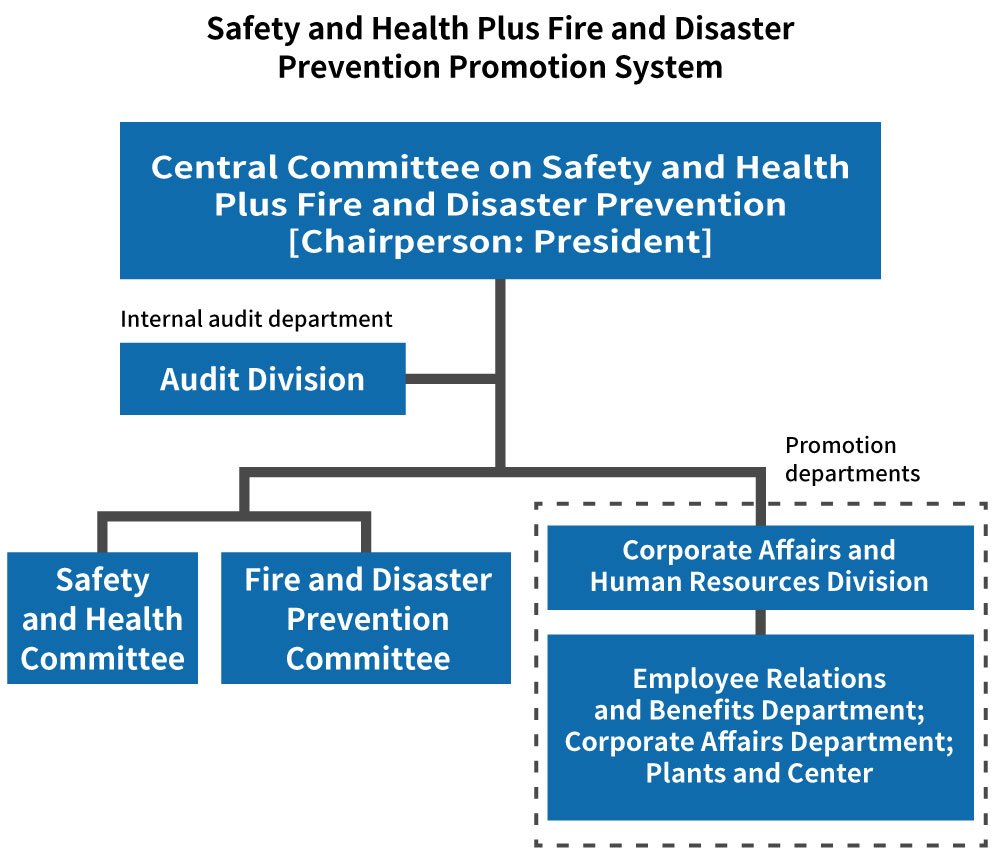

In accordance with safety and health management manual based on RBA Code of Conduct, Shinko has established a Central Committee on Safety and Health Plus Fire and Disaster Prevention, chaired by the President, to oversee each plant’s activities, work through PDCA cycle by analyzing accidents that have occurred, establishing company-wide measures and goals related to safety and health plus fire and disaster prevention, managing the progress of measures, and verifying the effects of measures and make improvements, and raise the level of safety and health.

In addition, each plant has established a Safety and Health Committee and a Fire and Disaster Prevention Committee, as well as a Health and Safety Liaison Committee with dispatch and outsourcing companies, where we discuss and implement initiatives for each plant on a monthly basis. We also share information between plants and companies about accidents that have occurred within the Company and the countermeasures taken, and work to prevent similar accidents.

Shinko has established Risk Assessment Standards and conducts risk assessments when starting a new operation, when changing an operational method, and for all operations once a year to reveal and assess potential risks, and carry out efforts to rectify dangerous points. We also implement safety patrols monthly by Safety and Health Committee members and specialized committee members to identify and improve dangerous points. To systematically reduce the danger of identified risks, each plant manages the progress of corrections and reports to the Central Committee on Safety and Health Plus Fire and Disaster Prevention. In FY2024, 1,803 corrective actions were completed company-wide.

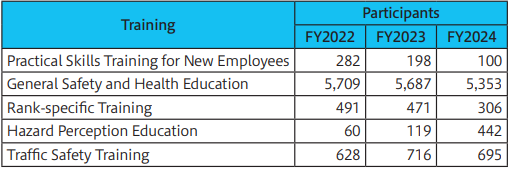

In addition to daily safety guidance, Shinko provides practical skills training for new graduates and mid-career hires working at manufacturing sites, annual safety and health training for all employees, rank-specific safety and health training, and periodic emergency drills.

In FY2024, in order to improve the hazard sensitivity of workers, we conducted Hazard Perception Education again in which we used special equipment to simulate industrial accidents. A total of 442 employees participated in the program.

In conjunction with nationwide activities such as the National Safety Week in July and Occupational Health Week in October, Shinko encourages all employees to participate in initiatives such as the solicitation of safety and health slogans. Through such initiatives, we are striving to boost the safety and health awareness of all employees.

Safety and Health Training Achievements in FY2024〔Shinko Group in Japan〕

Hazard Perception Education to Improve the Hazard Sensitivity

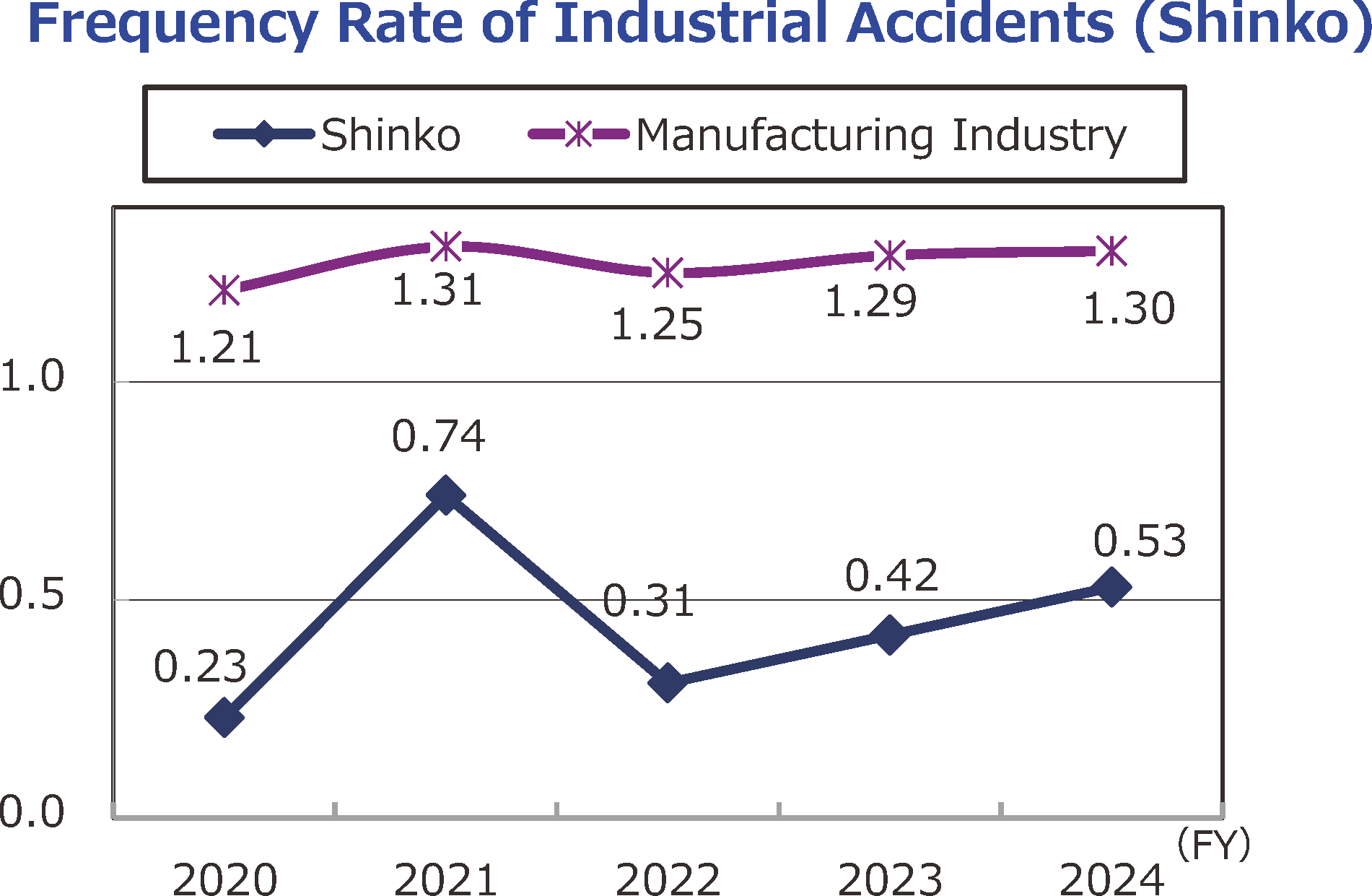

Occupational accident frequency rate at Shinko remains at a level below the nationwide average for the manufacturing industry, and in FY2024, Shinko had no accidents resulting in death or residual disability nor any similarly serious accidents.

In FY2025, we will continue to promote safety and health with the goal of achieving zero accidents resulting in death or disability as well as similar serious accidents.

Note: Frequency rate: An index indicating the frequency of industrial accidents, calculated based on the number of casualties due to industrial accidents (one day or more of absence from work and loss of body parts or functions) per 1 million total actual working hours

Shinko is committed to creating workplaces where employees can work safely and comfortably. Accordingly, in addition to regular monitoring of the work environment (noise, luminance, and heatstroke indicators), we have industrial doctors and nurses (public health nurses or registered nurses) perform the following actions.

In addition to statutory general and special health exams, Shinko has specific health exams based on an employee’s age (with 100% participation) and provides specific health guidance based on the results. For FY2024, specific health guidance was completed for 75% of eligible employees, exceeding the national target of 45%.

Shinko issues a regular Health Room Newsletter based on analyses of health examination results and provides information related to health promotion to foster self-care awareness among each and every employee.

In addition to subsidizing the costs of gynecological checkups, brain checkups, and lung checkups for early detection and treatment, Shinko also makes available subsidized in-house vaccination against seasonal influenza as an infectious disease control measure, and in FY2024, 2,052 employees (37.8% of all employees) who requested were vaccinated within the company.

Also, we have established a Health Measurement Corner in rest areas. The Health Measurement Corner lends out pedometers and tape measures and offers health measurement devices such as body composition analyzers, and blood pressure gauges, that employees are free to use.

We also promote healthy activities, such as walking, using a smartphone app and events that encourage people to stop smoking. Our cafeterias offer nutritionally balanced “smart meals” containing food items that contribute to health, as well as meals tailored to healthy themes on Food Education Day (19th of every month). In these ways, we cooperate with employee cafeterias and health insurance association to help employees maintain and increase their health.

Employee Cafeteria Menu: Smart Meals

As an internal consultation service, industrial doctors and nurses consult with employees about mental health care at the Health Room in each plant.

As an external consultation service, the contacts have been established at independent third-party counseling centers commissioned by Shinko and at health insurance associations, where consultation is available through clinical psychologists and other professional counselors.

Mental health education with the goal of raising awareness of mental-health issues is implemented according to rank, such as managerial, mid-career and new-hire employees. Shinko works on preventive measures for mental illness among employees while promoting both self-care and managerial care to detect and treat issues at an early stage. We also promote active efforts to improve the workplace environment and enrich dialogue, including through skills development training for the leader class.

In addition, we conduct annual stress checks with the aim of preventing (primary prevention) poor mental health. The results of stress check analysis are appropriately fed back to each department manager to promote proactive measures to improve the workplace environment.

In March 2025, Shinko obtained certification for the seventh consecutive year as an Outstanding Health and Productivity Management Organization (in the Large-Scale Corporate Category)” by the Ministry of Economy, Trade and Industry and Nippon Kenko Kaigi (Japan health council). We place the highest priority on management issues involving employee safety and health maintenance and engaged in a variety of initiatives in support of these efforts. By verifying and assessing their results, we will maintain our pursuit of continuous improvements to increase the efficacy of these measures and tailor them to individual situations.