SHINKO ELECTRIC INDUSTRIES CO., LTD.

SHINKO ELECTRIC INDUSTRIES CO., LTD.

Resources such as raw materials and water are indispensable for the manufacturing of the Shinko Group. However, there are now concerns that resources may become depleted due to loss of biodiversity and other factors. To prevent resource depletion, we recognize the importance of sustainable resource utilization and have made resource circulation one of the Shinko Group's material issues.

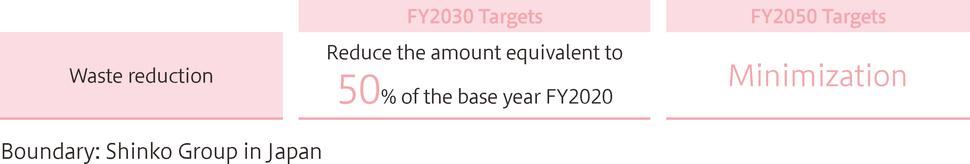

Therefore, we have set medium- to long-term environmental targets for "waste reduction" and "reduction of water use" to maximize effective use of resources and recycling, and are promoting activities aimed at transitioning to a circular economy and realizing a recycling-oriented society, while reducing risks to business continuity.

Waste Reduction

Waste ReductionThe Shinko Group utilizes various resources such as metals and plastics to manufacture its products. We view the waste generated from this process as valuable resources from a resource circulation perspective and continuously strive to recycle them.

We are actively promoting waste generation control, efficient use of raw materials, and conversion to resources with lower environmental impact based on Basic Act on Establishing a Sound Material-Cycle Society, which stipulates (1) reduction of waste generation, (2) reuse, (3) recycling, and (4) heat recovery.

Reporting boundary: Shinko Group in Japan

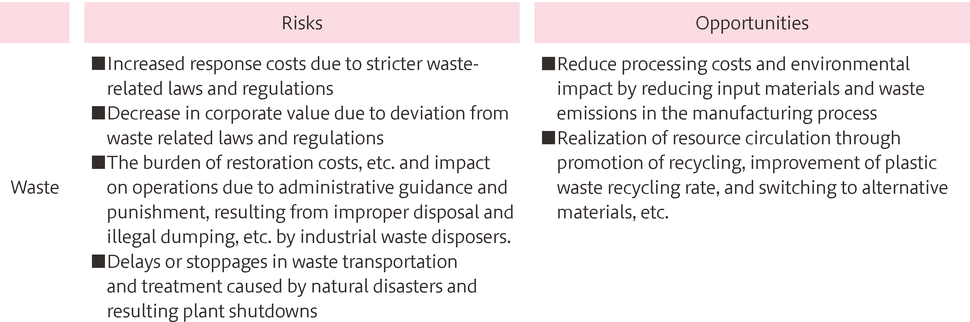

Key risks and opportunities related to waste

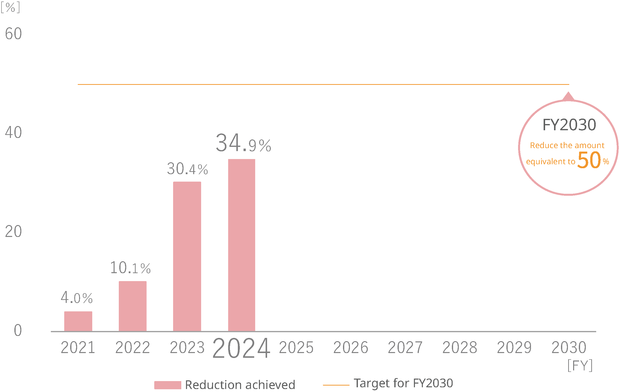

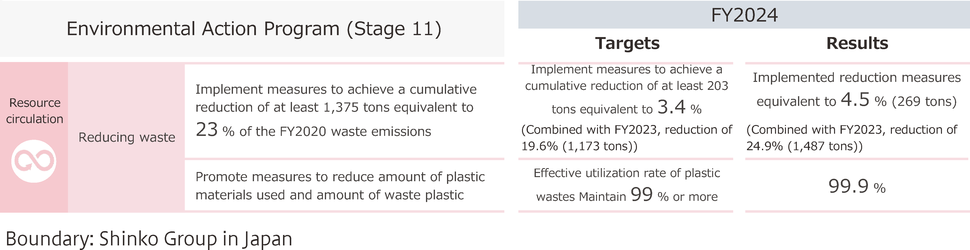

In FY2024, Shinko Group in Japan exceeded its target of "reducing waste at least by equivalent to 3.4% of FY2020 waste emissions," achieving a reduction equivalent to 4.5% (269 tons) and successfully meeting the goal. As a result, through our initiatives in FY2023 and FY2024, we reduced waste by the equivalent of 24.9%, surpassing the Environmental Action Program's target of "reducing waste at least by equivalent to 23% of the FY2020 waste emissions," and achieved this target one year ahead of schedule.

Through these initiatives, we have achieved a reduction equivalent to 34.9% of the 2030 target—reducing waste by an amount equivalent to 50% of the base year emissions—over the four years starting in FY2021. This progress indicates steady advancement toward achieving our medium- to long-term targets.

From FY2025 onward, we anticipate an increase in waste volume due to new line launches and production expansions, and will therefore pursue further waste reduction.

1. Promotion of the conversion of waste into valuable resources through thorough sorting

2. Reduction of debris and waste through process improvement

3. Weight reduction through dewatering treatment of high-moisture-content waste

4. In-house processing of waste liquids

5. Promotion of regeneration and reuse

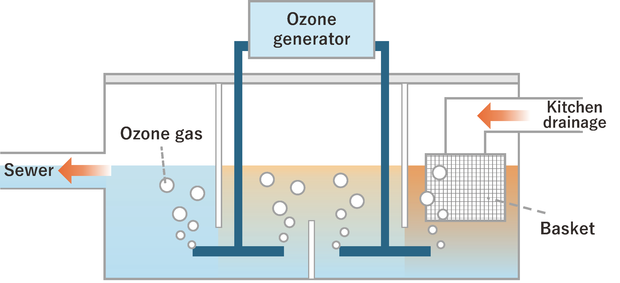

Wastewater from Shinko's employee cafeteria is drained through a grease trap to separate oils and food waste from the wastewater before it is discharged into the sewer system. Grease and food waste collected in grease traps not only cause pipe clogs and foul odors, but also require regular cleaning and the accumulated grease becomes waste.

To solve this problem, we installed an ozone generator that decomposes and sterilizes oil and other substances by injecting ozone gas into the grease trap. This resulted in reduced oil content and sediment, decreased foul odors and cleaning frequency, as well as a reduction of 27.6 tons in waste over the eight-month period from August 2024 to March 2025. Another advantage is that it can be decomposed and sterilized with minimal environmental impact.

Image Diagram inside the Grease Traps

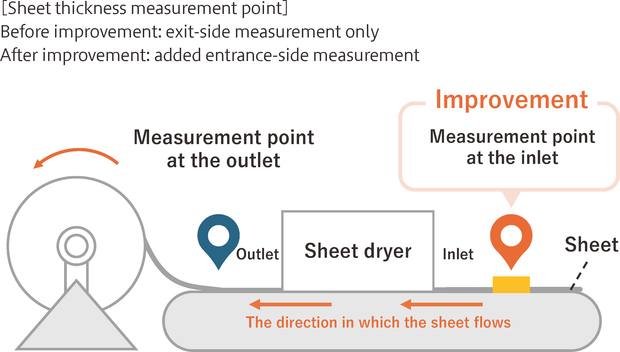

Shinko successfully reduced waste by adding a measurement point for sheet thickness during the sheet forming process for ceramic sheets used in ceramic electrostatic chucks.

Previously, sheet thickness was measured only at the outlet of the sheet dryer. In this case, if the sheet thickness was found to be out of specifications after passing through the dryer, the portion that had entered the dryer at that point became non-standard and was discarded. We therefore added a sheet thickness measurement point at the inlet of the dryer as well. This reduced the number of non-standard sheets, resulting in a waste reduction of 21.8 tons over the 11-month period from May 2024 to March 2025.

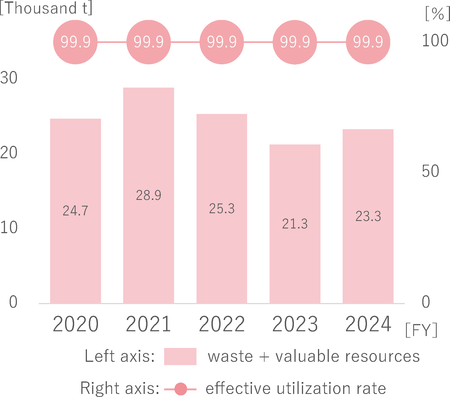

The Shinko Group in Japan achieved zero emissions in FY2003 by effectively utilizing wastes and reducing landfill disposal and simple incineration (disposal methods not making effective use of waste heat from incineration or residual materials after incineration) to zero in order to create a recycling-oriented society. Since then, the effective utilization rate for waste has remained close to 100%, and we continue to maintain zero emissions.

Note: The effective utilization rate will not reach 100% since waste for which there is no effective utilization method and waste brought to local government-operated disposal sites that do not practice effective utilization (general waste from business activities) is not subject to zero emissions calculations.

Trends in Waste + Valuable Resources and Effective Utilization Rate

Shinko also succeeded in reducing waste by 1.4 tons over FY2024 by converting polyethylene containers that had held chemicals and previously been treated as waste due to chemical residue into valuable resources through cleaning. It will also be implemented at Arai Plant (Myoko City, Niigata Prefecture) starting in FY2025.

Polyethylene Chemical Container

Plastic is a widely used material because of its usefulness, but at the same time, its mass production and disposal have been cited as a factor in various global problems such as climate change and marine plastic pollution. To address such plastic-related issues, Japan enacted the "Plastic Resource Circulation Act" in June 2021. As a major emitter as defined in this Law, Shinko has established the "Promote measures to reduce amount of plastic materials used and amount of waste plastic" as a new item of the Environmental Action Program (Stage 11) and has set the annual target of “Effective utilization rate of plastic wastes: maintain 99% or more” in order to contribute to the resolution of issues related to plastics, and we is promoting this initiative. The result of FY2024 is 99.9%, achieving the target.

Key Initiatives

・Switching from plastic to paper and other materials for packaging materials

・Switching from disposable to reusable items (e.g. switching from disposable containers to reusable containers)

・Converting waste plastics into valuable resources by ensuring thorough separation

We will continue to work on reducing waste plastic and promoting its recycling.