SHINKO ELECTRIC INDUSTRIES CO., LTD.

SHINKO ELECTRIC INDUSTRIES CO., LTD.

Halting and reversing the urgent global issue of biodiversity loss is an important challenge for our company's sustainability, as our business activities both benefit from and impact the bounty of biodiversity.

The Shinko Group has the Environmental Policy to contribute to the creation of an abundant society through countermeasures for climate change, effective utilization of resources and conservation of biodiversity, and have established medium- to long-term environmental targets for biodiversity conservation. We are working toward nature positivity and the realization of a society living in harmony with nature by driving efforts to conserve biodiversity and reduce negative impacts on ecosystems in our business activities.

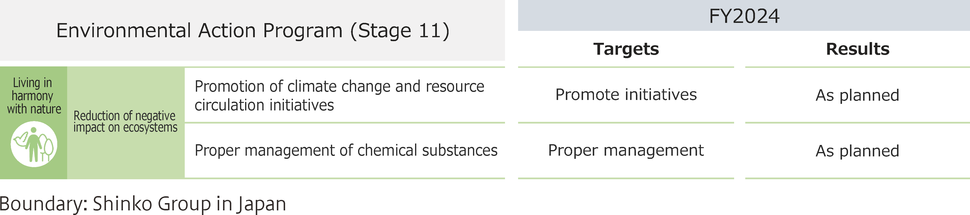

Reduction of Negative Impact on Ecosystems

Reduction of Negative Impact on EcosystemsAs the conservation of biodiversity is essential to Shinko's sustainable corporate activities, it will reduce the negative impacts of its business operations on ecosystems through initiatives such as "Promote climate change and resource circulation initiatives" and "Proper management of chemical substances."

Reporting boundary: Shinko Group in Japan

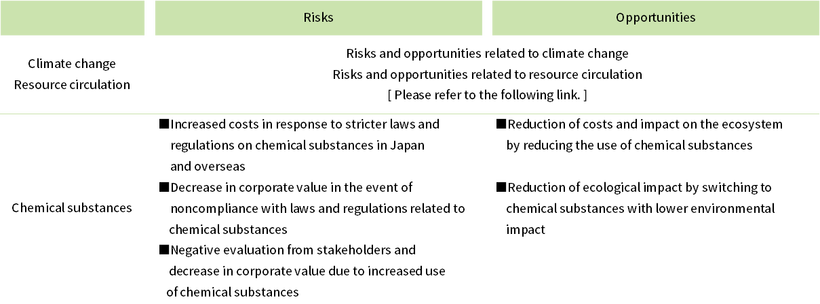

Key risks and opportunities related to negative impact on ecosystems

> Climate Change Initiatives

> Resource Circulation Initiatives

The Shinko Group in Japan recognizes that its efforts to address climate change and resource circulation also contribute to biodiversity recovery, thereby serving to reduce negative impacts on ecosystems. Please see the link below.

> Climate Change Initiatives

> Resource Circulation Initiatives

Chemical substances make people's lives more convenient, but they can have a significant impact on human health and ecosystems. However, chemical substances are indispensable for the manufacture of electronic components. In order to reduce the negative impact of chemicals on people and ecosystems, the Shinko Group in Japan has established Control Standards for Chemical Substances, and we control and use chemical substances properly. In addition, we are working to reduce the use and emission of chemical substances.

Chemical substances used in product development and manufacturing are controlled by checking the transaction volume and the amount of emissions and movement to the environment (atmospheric air, water, and soil) based on the PRTR system1. When previously unused chemical substances are to be processed, they will be used properly after conducting a risk assessment to identify any environmental risks.

1 PRTR system: Pollutant Release and Transfer Register system is the system for collecting and reporting information about chemical substances that are emitted and moved to the environment. This system is defined in the Ordinance for Enforcement of the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof and is imposed on business operators handling chemical substances.

The information on the chemical substances contained in purchased products is identified and controlled based on chemSHERPA®2, and Shinko has built a system which enables us to respond to customer requests and so that various laws and regulations can be met. We request major suppliers of materials and components to build the CMS (Chemical substances Management System) as a measure to keep hazardous substances out of our products. In addition, we audit chemical substance control status periodically and continually. If an insufficiency is detected, we request that the supplier to correct it and support its improvement.

> Supply Chain / Green Procurement

2 chemSHERPA®: Chemical information SHaring and Exchange under Reporting PArtnership in supply chain.

chemSHERPA® is the data generation tool for obtaining and disseminating information on the chemical substances contained in products and can be used by all business operators involved in processes from raw material procurement to product finishing.

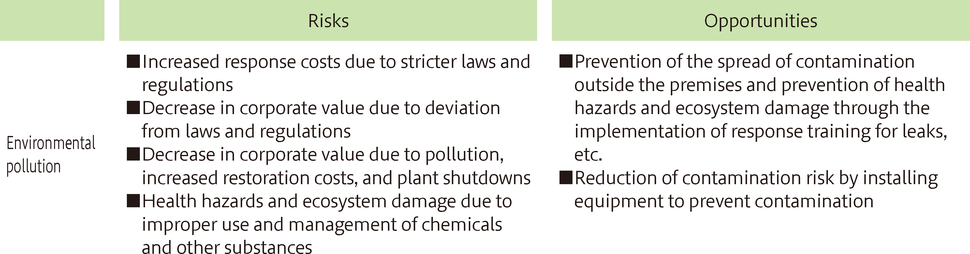

To minimize impacts on the environment and neighboring stakeholders, the Shinko Group continuously strives for improvement through its environmental management system, focusing on preventing and minimizing environmental pollution.

Key risks and opportunities related to environmental pollution

Thorough management through the following measures:

Shinko uses natural gas because it produces the lowest CO2 emissions among fossil fuels and releases the smallest amounts of the environmentally harmful substances that are contained in soot and smoke (dust, sulfur oxides, and nitrogen oxides) during combustion.

Shinko regularly measures soot and smoke by setting voluntary control standards that are stricter than the national and prefectural emission standards. There were no exceedances of either the voluntary control standards or the emission standards in FY2024.

Some exhaust emissions from manufacturing equipment and wastewater treatment facilities also contain hazardous substances. Such exhaust gas is input to an exhaust gas treatment device (scrubber) so that hazardous substances can be removed and discharged to air.

Each piece of equipment that uses fluorocarbons is given an equipment ID, and a label with the ID is attached to the equipment to manage inspection records, disposal and other details are managed in a ledger.

Shinko strives to prevent leakage of fluorocarbons and detect leakage at an early stage by conducting inspections every three months. If any equipment malfunction is found as a result of these inspections, etc., the equipment is repaired as soon as possible.

Wastewater discharged from plants is detoxified and released into rivers or sewers under strict control.

The quality of water discharged from Shinko's plant is regulated by the Water Pollution Control Act and the Sewerage Act, but Shinko has established voluntary control standards that are stricter than the national and prefectural effluent standards, and it measures water quality regularly to ensure thorough management of the quality of its wastewater.

There were no exceedances of voluntary control standard values or effluent standard values in FY2024.

Shinko is taking thorough measures to prevent leakage in the storage of chemical solutions and waste liquids.

Tanks are systematically updated after a certain number of years, based on the material and the contents. Also, we have installed liquid containment walls around our tanks to prevent leaks in and outside our premises.

Liquid containment walls, tanks, piping, etc. are regularly inspected to detect deterioration and anomalies at an early stage, leading to the prevention of leaks.

As a leak prevention measure, each plant conducts annual response drills simulating chemical leaks at designated locations. These drills ensure prompt action and appropriate response in the event of a leak, enabling employees to learn the proper use of protective gear and response procedures.

There was no leakage in FY2024.

Shinko has established voluntary control standards for items based on the Soil Contamination Countermeasures Act and ordinances, which are stricter than the legal standards, and conduct periodic inspections. We confirmed that there was no soil or groundwater contamination on our company premises in the FY2024.

Comprehensive safety inspections are conducted twice a year at each plant (14 inspections in total) by managers in individual facilities management departments. These inspections involve managers working at plants other than the one being inspected in checking utility equipment, 5S conditions, and other factors. By implementing improvements for issues identified during these inspections and disseminating the issues horizontally, Shinko promotes stable utility supply and the elimination of occupational accidents, while also contributing to environmental conservation and legal compliance.

In accordance with the Act on Waste Management and Public Cleaning, Shinko outsources disposal properly to industrial waste disposal contractors and confirms proper disposal once a year through on-site inspections, etc. No improper disposal was found at the contractors in FY2024.

With regard to PCBs (polychlorinated biphenyls), the Shinko Group in Japan has completed the disposal of all high-concentration PCB waste and currently holds no low-concentration PCB waste. However, to prevent any missed disposal after the deadline, we once again carried out an inspection to identify equipment that might contain low-concentration PCBs. We will properly dispose of any PCB-containing equipment identified through analysis, in accordance with the Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes.